ABBS Option

Option shown on this page is available for all Model Years of OKA NEV.

Option Description

The ACG ABBS 48-12 (Active Battery Balancing System) individually balances four 12 Volt Lead-acid batteries that are connected in series for 48 Volt nominal Battery Stack Voltage.

It is intended to be used in conjunction with a separate pre-existing battery charger as part of a high performance battery system.

All voltage monitoring and fault detection circuitry and functionality is integrated.

The ACG ABBS 48-12 employs an Auxiliary Battery or an alternative storage cell to transfer charge to or from each individual battery in the series connected Battery Stack.

A mode control port provides two operating modes, timer mode and continuous mode.

In timer mode, once the balancing operation is completed, the ACG ABBS 48-12 goes into a low power state for a programmed time and then periodically re-balances the batteries.

In continuous mode, the balancing operation continues even after the batteries are balanced to their programmed termination voltage for as long as the power is applied to the ECU terminals.

The balancing operation itself is stand-alone and can operate independent of whether the battery stack is being charged, discharged, or both.

Because the ACG ABBS 48-12 balances voltages, it will properly balance the battery voltages when the stack is being concurrently charged and/or discharged, since the voltage across the batteries will average out over time as the ACG ABBS 48-12 repeatedly cycles through them.

The ACG ABBS 48-12 balances batteries using an Auxiliary Battery or an alternate storage cell as a charge reservoir.

Switching Module contains Solid State high current switching relays which are controlled in a pre-programmed sequence to connect each individual battery in the stack to an auxiliary cell.

Background

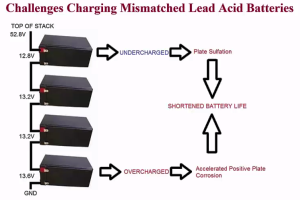

Whenever several batteries are connected in Series to form a higher Voltage Battery Stack, the over all Battery Stack performance is limited by the "weakest" individual Battery in the Stack.

Click Image for larger size

Batteries in the stack become mismatched due to following reasons:

- Manufacturing tolerances / defects

- Varying self-discharge currents

- Accrued aging differences

- Imbalanced loading

- Battery replacement in the stack

Result of Operation with mismatched Series connected Lead-Acid Battery Stacks:

Capacity and SoC mismatch create charging problems, which reduce battery lifetime.

Capacity and SoC mismatch reduce run time.

Active Battery Balancing

Basic Principle

Active Battery Balancing methods remove charge from one or more high charge batteries in a Battery Stack and deliver the charge to one or more low charge batteries.

Since it is usually impractical to provide independent charging for all the individual batteries simultaneously, the balancing charge must be applied sequentially.

Taking into account the charging times for each of the batteries, the equalization process is also very time consuming, with charging times measured in hours.

Some Active Battery Balancing schemes are designed to halt the charging of the fully charged batteries and continue charging the weaker batteries till they all reach full charge thus maximizing the Battery Stack's charge capacity.

Several Active Battery Balancing schemes have been proposed and there are trade-offs between the charging times, efficiency losses and the cost of components.

The ACG ABBS 48-12 stand-alone multi-cell battery balancer uses the most efficient and cost effective balancing method.

Auxiliary Battery Method

With this method an Auxiliary Battery is switched sequentially across each battery in the series chain.

The Auxiliary Battery averages the charge level on the batteries by picking up charge from the battery with higher than average voltage and dumping the charge into battery with lower than average voltage.

Only recently this method became more practical due to advances in capabilities of Electronic Solid State Relays (SSR), which are now available in current ratings that are necessary for practical Active Battery Balancing System.

The ACG ABBS 48-12 stand-alone multi-cell battery balancer uses this balancing method.

System Operating Principle

The ACG ABBS 48-12 is a stand-alone multi-cell battery balancer for 48 Volt Battery Stacks that are using four 12 Volt Lead-acid batteries connected in series.

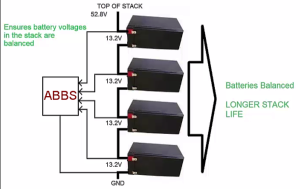

Click Image for larger size

Balancing works by absorbing charge from higher voltage batteries and transferring that charge to lower voltage batteries so that all are charged equally.

Charge is transferred using a lower capacity battery that is sequentially connected across the batteries in the stack.

Not only does this battery transfer charge, but the energy in the transfer battery adds to the total energy in the stack, thus increasing overall capacity.

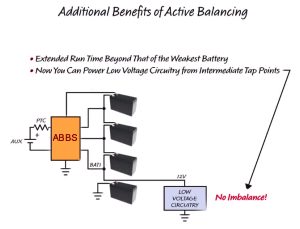

Click Image for larger size

The ACG ABBS 48-12 is designed for stand-alone operation and does not require a separate microprocessor or other control circuitry.

With the ACG ABBS 48-12 , one battery in the stack can be replaced and will be quickly balanced to the remaining batteries.

The ACG ABBS 48-12 employs an auxiliary battery storage cell to transfer charge to or from each individual battery in the stack.

The ACG ABBS 48-12 System consists of separate solid state electronic modules, which provide system control, the battery switching operation and optionally battery monitoring.

Further, additional modules can be stacked to balance higher voltage series battery packs.

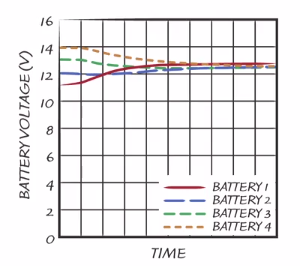

The graph below shows the initially out of balance Battery Stack Voltages to converge with time as the Battery Stack is being balanced by ACG ABBS 48-12.

FEATURES

-

Single ABBS Basic Unit Balances

48 Volt nominal Battery Stack

(Four 12V Lead-acid Batteries connected in Series) - All Solid State Design

- Stack-able and Expandable to Balance Larger Series Battery Packs

-

Stand-alone Balancing Operation:

Requires NO External micro processor or additional Control Circuits - Balancing Current limited by PTC Thermistor

- Continuous Mode and/or Timer Mode

- Programmable Over Voltage and Zero Voltage Fault Thresholds

- Programmable Termination Time and Termination Voltage

- All Optional functions are software controlled

- Dimensions: 7.875 x 4.78 x 1.57 inches

- Power Consumption: less than ¼ Watt

- Weight: 16 ounces (435 grams)

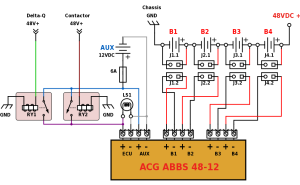

Wiring Diagram

Click Image for larger size

IMPORTANT NOTE:

Auxiliary Battery Negative Pole (AUX -) is Isolated from Vehicle Chassis Ground.